The following example illustrates the features of the product in practical applications:

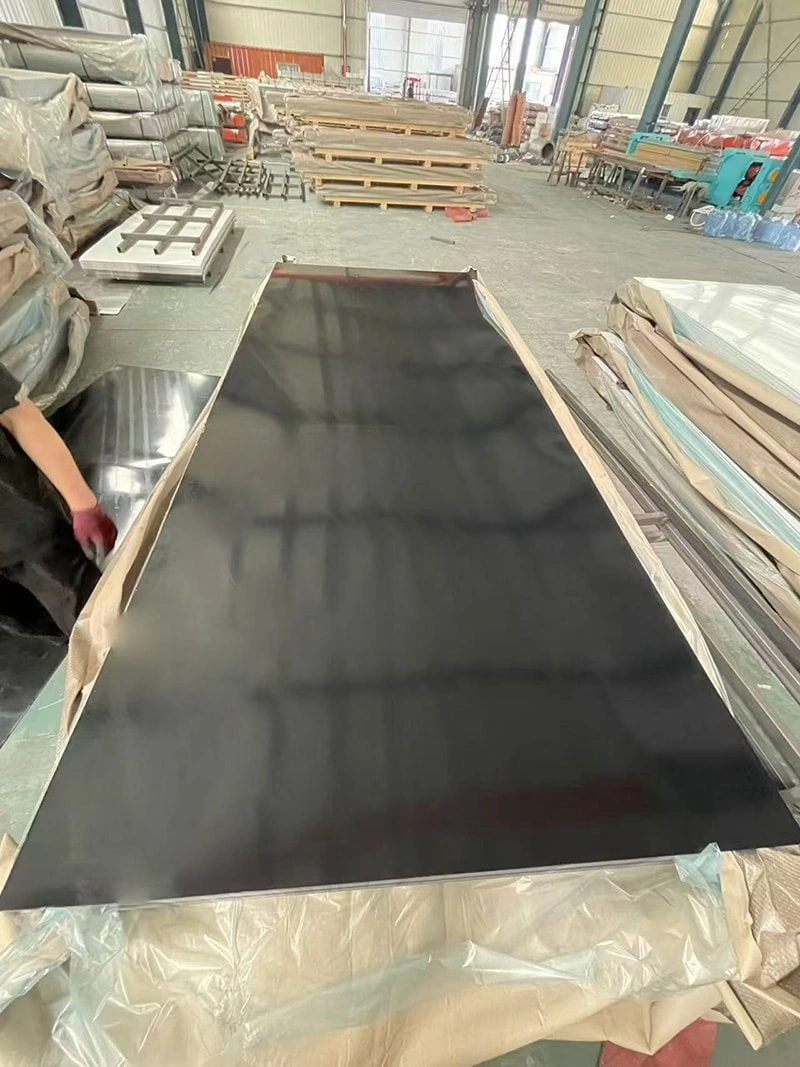

Base Plate Selection: AZ150 (aluminized zinc coating weight: 150 g/m²); G345A high-strength aluminized zinc steel sheet (composition: 55% aluminum, 43% zinc, and 1.6% silicon).

Coating Type: Fluorocarbon coating (PVDF).

Coating Structure: 2/2 (two coats, two cures).

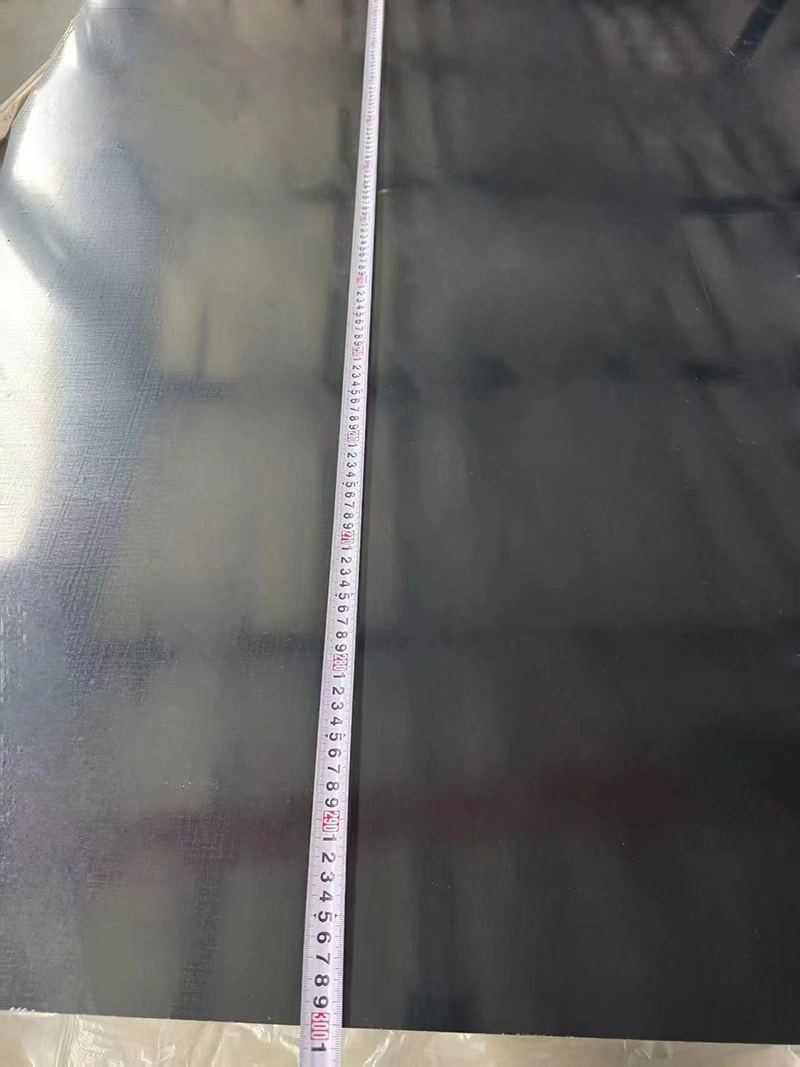

Coating Thickness: 5+20/5+20 μm.

Corrosion Resistance Data:

· 5% NaCl, 35°C, 1000 hours: Field area - Good; Scribe area - No blistering within 2 mm.

QUV Test Data:

· 2000 hours: Maximum color difference ≤ 2; Gloss retention ≥ 90%.

The above data indicate that the aluminized zinc color-coated sheet (AZ150, G345A, PVDF) is highly suitable for buildings or other facilities in extreme environments, offering excellent corrosion and weather resistance. Moreover, major steel mills guarantee a service life of over 20 years for this type of steel sheet. Additionally, high-strength steel sheets are widely used abroad due to their cost-effectiveness and represent a developing trend in the domestic market.